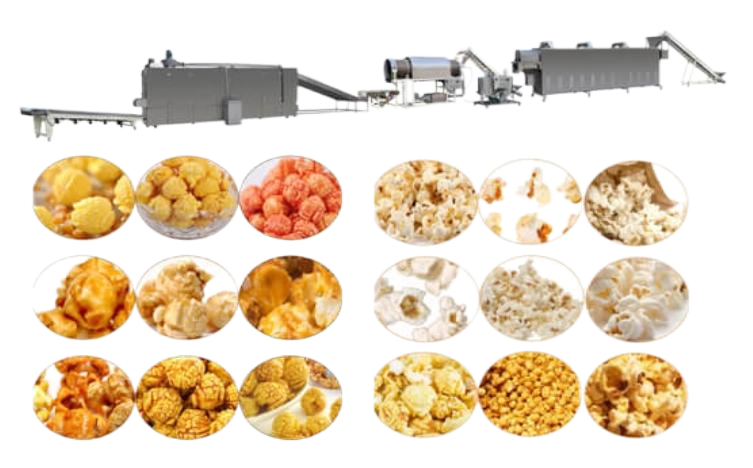

Popcorn Processing Line

Popcorn processing line includes popcorn machines, caramel popcorn production lines, and popcorn packaging equipment.

What is Popcorn?

Popcorn is a delicious snack perfect for holidays, especially while watching a movie, or whenever you’re craving something sweet, salty, or spicy. It can be enjoyed as individual kernels or formed into popcorn balls—an amusing and delightful treat.

Sample

Popcorn Processing Equipment

Popcorn Machine

Popcorn Production Line

Vertical Form Fill Seal Machine

Premade Pouch Packing Machine

التعليمات

ask us

anything

How do you guarantee batch-to-batch consistency in popcorn texture and expansion?

Our Intelligent Expansion Control System utilizes variable-frequency dual drives and real-time die temperature monitoring. This ensures:

- Stable Expansion Ratio: Maintains ±3% deviation (vs. industry ±8-10%), achieving your target ratio (e.g., 1:12) consistently.

- Superior Product Uniformity: Every kernel pops to the desired size and texture, minimizing waste and rejected batches.

- Energy Savings: Consumes ≤0.11 kWh/kg (40% lower than conventional systems).

Can your seasoning system handle sticky coatings (like caramel) without clumping?

Absolutely. Our Vortex Multi-Layer Coating Technology combines:

- Precision Liquid Binding: Applies syrup/oil evenly as a base layer.

- Airflow-Powered Powder Adhesion: Uses vortex dynamics to embed seasoning (cheese, spices, caramel powder) with ≥94% adhesion rate.

- Zero Clumping: Eliminates product loss from stuck seasoning in the drum. Saves ~$22k/year in raw materials (based on case studies).

Can your lines accommodate small R&D batches?

Yes. Our Popcorn Production System is designed for innovation:

- Micro-Batch Capability: Start trials with just 2kg of raw material.

- Rapid Changeovers: Switch molds/flavors in ≤15 minutes.

- Recipe Library: Store & recall 50+ parameter presets for instant replication.

How do you achieve shelf life over 10 months with minimal breakage?

Our Gentle-Touch Nitrogen Packaging integrates:

- Air-Cushion Conveyance: Floating transport reduces impact (<0.5% breakage vs. 3-5% industry standard).

- Vertical Form-Fill-Seal (VFFS): Ensures precise pouch sealing.

- O₂ Exclusion: Nitrogen flushing cuts residual oxygen <0.8%, extending shelf life to 12+ months reliably.

Customer Reviews

“As a small producer, Esper’s R&D equipment was crucial. We tested 15+ recipes at 2kg/batch, launching 3 bestsellers in 6 months. Their nitrogen packager gives artisanal quality with 0.5% breakage and 11-month shelf life – critical for export. Now scaling with their 120 packs/min line!.”

Serina

“Nitrogen packaging extended shelf life to 10 months with only 0.5% breakage. Walmart complaints down 95%, won 3 international clients in 3 months.”

alireza javadi

TAKE THE FIRST STEP.

WE WILL DO THE REST.

7 * 24 Support

7 * 24 Support  Remote Support

Remote Support  Global Coverage

Global Coverage