Chicken Feet Processing Machine

Chicken feet processing machines include small peeling machines, large chicken feet peeling machines, chicken feet peeling production lines, and chicken feet packaging machines.

Sample

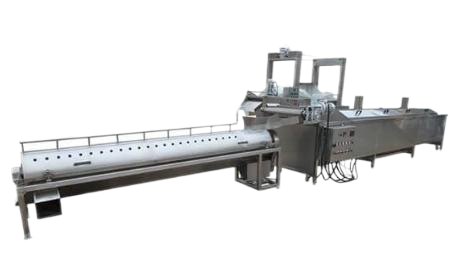

Chicken Feet Processing Line

Sesame Peeling Machine

Large Chicken Foot Peeling Machine

Production Line For Peeling Chicken Feet

Chicken Feet Flow Packer

Chicken Premade Pouch Packing Machine

Vertical Form Filling Seal Machine

よくある質問

ask us

anything

What is the processing capacity of the sesame peeling machine?

Our peeling machines achieve an industry-leading peeling rate of ≥98% while maintaining a remarkably low breakage rate of <2%. Advanced roller pressure control and water spray systems ensure the skin is cleanly removed without damaging the delicate tendons or bones, maximizing your yield and product value.

Can your equipment handle chicken feet of varying sizes?

Absolutely. Our peeling machines feature adjustable roller spacing and speed settings. This adaptability allows them to efficiently process a wide range of chicken foot sizes commonly found in markets worldwide (typically 40-80g per foot), ensuring consistent results regardless of batch variations.

How easy is it to operate and maintain the equipment?

Designed for user-friendliness and minimal downtime. The intuitive multi-language touchscreen interface provides clear operation guides. Daily cleaning takes only 15-20 minutes thanks to quick-release components and food-grade stainless steel construction. Routine maintenance is simple and guided by on-screen prompts. Remote diagnostics also help prevent major issues.

What packaging options are available for processed chicken feet?

We offer versatile solutions to suit your market needs:

- Flow Wrapping (Pillow Packs): Ideal for retail portions (200g-1kg), speeds up to 60 packs/min.

- Premade Pouch Packaging: For premium presentation, supports vacuum sealing to extend shelf life.

- Vertical Form-Fill-Seal (VFFS): Cost-effective for bulk packs (1kg-5kg).

All systems support date coding and batch tracking.

Do you offer complete, customized production line solutions?

Yes, we specialize in turnkey solutions. From receiving raw feet → soaking → scalding → peeling → chilling → seasoning/marinating → weighing → packaging → palletizing, we design the optimal layout based on your factory space, target capacity (500kg to 5 tons/day), and specific product requirements. We integrate auxiliary equipment like chillers and conveyors seamlessly.

Customer Reviews

7 * 24 Support

7 * 24 Support  Remote Support

Remote Support  Global Coverage

Global Coverage