Fish Ball Production Line

Fish ball production line include fish descaling machines, fish cutting machines, fish meat separators, bowl cutters, meatball forming machines, meatball filling machines, and fish ball packaging machines.

Fishballs make a delicious appetizer. When paired with your favorite side dishes, they can also be served as a tasty main course—whether boiled, steamed, fried, or added to soup.

The process of making fishballs involves a few steps: first, scale and debone the fish; then remove the skin, finely chop the fish into a paste, and mix it with other ingredients; finally, shape the mixture into balls.

Sample

Fish Ball Making Machines

Fish Descaling Machine

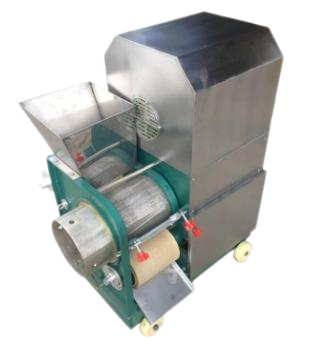

Bowl Cutter

Fish Cutting Machine

Fish Cutting Machine

Fish Cutting Machine

Fish Cutting Machine

Premade Pouch Packing Machine

Vertical Form Fill Seal Machine

Flow Packing Machine

よくある質問

ask us

anything

How adaptable is the production line to fish species?

The standard configuration is suitable for white fish (cod/bream, etc.), and frozen fish needs to be equipped with a -25℃ quick-freezing warehouse. The chopper is equipped with a temperature control system (0-4℃ operation) to ensure that the gel strength of the fish paste is ≥800g·cm

How to configure the production capacity?

The basic line (EFB-300 model) includes the entire process of descaling → packaging, with a production capacity of 300kg/h (about 18,000 pieces/hour). 8-hour shift production is 2.4 tons, with 6 staff (traditional manual lines require 20 people)

How to ensure the elasticity of fish balls?

Triple process control:

Meat extraction rate ≥ 65% (stainless steel drum separator)

Salt pounding time adjustable (chopping machine ± 15 seconds accuracy)

Gradient heating cooking (40℃→90℃ temperature control chain)

How to solve the problem of stuffing leaking in fish balls with stuffing?

Double spiral encrusting and forming machine (EPF-200 model) adopts pressure closed loop control, stuffing error ≤ 3%, breakage rate < 0.5%

Customer Reviews

7 * 24 Support

7 * 24 Support  Remote Support

Remote Support  Global Coverage

Global Coverage