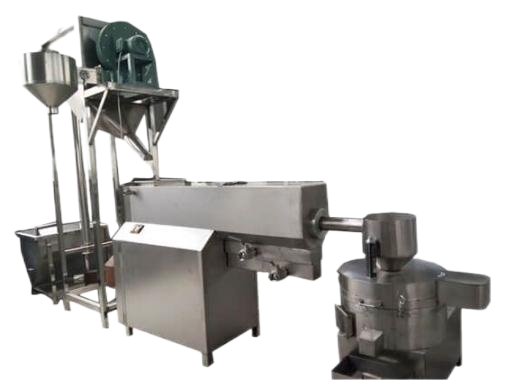

Sesame Paste Machine

Sesame paste machines, including sesame cleaning machine, sesame peeling machine, multifunctional sesame roasting machine, peanut butter machine and sesame packing machine

Sesame paste is a condiment made by grinding roasted sesame seeds, rich in proteins, amino acids, vitamins, and minerals. It comes in two varieties: white sesame paste and black sesame paste. The production process involves four steps—cleaning, peeling, roasting, and grinding the sesame seeds—after which the delicious sesame paste is ready to enjoy.

Sample

Sesame Paste Production Line

Sesame Cleaning Machine

SesamePeeling Machine

Multifunctional Sesame Roasting Machine

Peanut Butter Machine

Paste Pouch Packing Machine

Vertical Form Fill Seal Machine

Часто задаваемые вопросы

ask us

anything

What is the standard capacity of this sesame paste production line?

Our standard configuration allows us to process 300-500 kg of raw sesame seeds per hour, producing 250-400 kg of refined sesame paste. The specific capacity can be adjusted and expanded based on the cleaning and peeling efficiency, grinder power, and packaging speed. We offer equipment solutions with varying capacity levels.

How efficient is the sesame peeling machine?

Our high-efficiency sesame peeling machine utilizes flexible friction/airflow/water-washing peeling technology, achieving a consistently high peeling rate of ≥98% while minimizing sesame kernel breakage to <2%, ensuring the quality and oil yield of the final paste.

Can the grinder (peanut butter machine) grind sesame paste to a very smooth and fine consistency?

Yes, our high-power colloid mill uses a specially customized grinding head, which can grind sesame paste to a very fine and smooth consistency. The fineness can typically reach ≥200 mesh, or even higher (such as 300 mesh), meeting the ultimate silky texture demanded by high-end sauces. The equipment features an adjustable grinding gap.

Can the packaging machine handle sesame pastes of varying viscosities and bag sizes?

Yes, our vertical packaging machine for liquids/preformed pouches is specifically designed for viscous sauces such as sesame paste and peanut butter. It is equipped with a servo-driven pump and special filling valves to ensure precise metering of high-viscosity sauces (with an accuracy of ±1-2%). By replacing molds and adjusting parameters, it can easily accommodate different preformed bag or roll film sizes (e.g., 100g, 250g, 500g bags) and bag shapes with varying openings.

Sesame paste has a high oil content. Is the equipment easy to clean?

All key equipment in the entire line (grinder, hopper, piping, etc.) is made of food-grade SUS304 stainless steel with a surface finish of Ra ≤ 0.8μm. We strongly recommend and support the optional CIP (Clean-In-Place) system. Its zero-dead-spot design and dedicated cleaning procedures effectively remove grease residues, ensuring hygiene and compliance with international certifications such as EHEDG. The manual cleaning section is also designed for easy disassembly and maintenance.

Customer Reviews

7 * 24 Support

7 * 24 Support  Remote Support

Remote Support  Global Coverage

Global Coverage