Cookie Production Line

Cookie production line, including flour mixing machine, biscuit machine, hot air oven and cookie packaging machine.

Cookies are a delicious treat suitable for any occasion, which is why they’re loved by everyone. People often enjoy cookies with milk, as this is the most popular pairing.

Baking delicious cookies involves just a few steps: mix flour with other ingredients of your choice, shape the dough, and bake. You can make them sweet or salty, crispy or fluffy, round or in various shapes for perfect results.

Sample

Cookie Processing Machines

Flour Mixing Machine

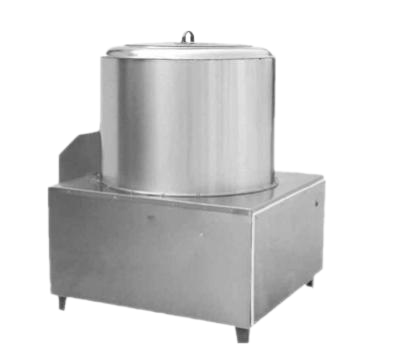

Biscuit Machine

Convection Bread Oven

Premade Pouch Packing Machine

Vertical Form Fill Seal Machine

Flow Packing Machine

คำถามที่พบบ่อย

ask us

anything

What types of biscuits are suitable for this biscuit production line?

The core equipment of our production line is optimized to flexibly produce a variety of common biscuit types, including tough biscuits (such as soda crackers), crisp biscuits (such as cream cookies) and cookies. The standard configuration capacity range is 200-800 kg/h (depending on the size, thickness and recipe of the biscuits). Please let us know your target product type and expected output, and we will recommend the most suitable model configuration for you.

How automated is the production line?

The production line is designed for high automation. Under the standard configuration, the core processes (mixing, forming, baking, cooling, packaging) can be continuously automated. The main links that require operators are: raw material feeding monitoring, equipment start and stop control, finished product sampling and packaging coil replacement. A typical production line (500 kg/h capacity) usually requires 2-3 skilled operators.

Is it complicated to replace biscuit molds?

Our biscuit forming machine adopts modular mold design and quick clamping device. Experienced operators can usually complete the replacement of molds of common shapes (such as round and square) within 15-30 minutes. Clear mold library management can reduce switching time.

What packaging materials and bag types does your packaging machine support?

Vertical Forming Pouch Packaging Machine (VFFS): Suitable for pillow-shaped bags, four-side sealed bags, using roll film (such as OPP/CPP, PET/PE composite film).

Premade Pouch Packaging Machine (Premade Pouch): Suitable for printed self-supporting bags, zipper bags, and special-shaped bags to enhance the appearance of the product.

Flow Wrapper: Suitable for secondary packaging of long biscuits or bag-in-box.

The specific choice depends on your product form, shelf life requirements and market positioning. We can recommend according to needs.

What should be paid attention to when maintaining the equipment?

The equipment is equipped with detailed Chinese/English operation and maintenance manuals. Daily maintenance mainly focuses on cleaning, lubrication of key components (such as chains, bearings) and inspection of wearing parts (such as cutting knives, sealing strips). We provide:

Operation and maintenance training (conducted on-site during installation).

Global spare parts supply network to ensure fast delivery of common spare parts.

1-year standard warranty (covers manufacturing defects).

Remote technical support (phone, email, video).

Optional extended warranty or annual maintenance contract.

Customer Reviews

7 * 24 Support

7 * 24 Support  Remote Support

Remote Support  Global Coverage

Global Coverage