Hamburger Making Machine

Hamburger making machines, including flour mixing machine, dough kneading machine, dough divider, bowl cutter, automatic hamburger patty machine, automatic belt frying machine and hamburger packing machine.

Two round slices of bread, a cooked patty made from ground beef, pork, turkey, or chicken, along with lettuce, bacon, tomatoes, onions, pickles, cheese, and condiments like mustard, mayonnaise, ketchup, and relish—all these come together to form one of the world’s most popular treats: the hamburger.

Our automated hamburger production systems solve these core issues with:

- Precision forming: ±1% weight tolerance for every patty

- Integrated cooking: Oil consumption reduced by 30% vs conventional fryers

- AI-driven assembly: 99.2% ingredient placement accuracy

- Scalable output: 2,000-20,000+ burgers/hour on single line

Sample

Fully Automated Hamburger Production Line

Flour Mixing Machine

Dough Kneader

French Fries Frying Machine

Bowl Cutter

Hamburger Patty Maker

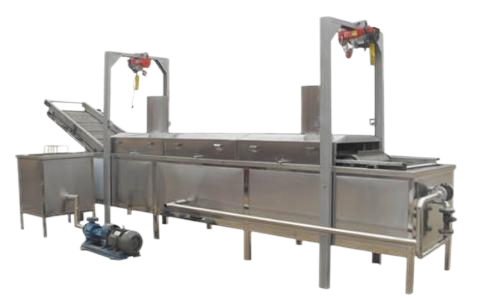

Conveyor Belt Deep Fryer

Premade Pouch Packing Machine

Vertical Form Fill Seal Machine

Flow Packing Machine

คำถามที่พบบ่อย

ask us

anything

How much labor can this hamburger production line save compared to manual production?

Our fully automated lines significantly reduce labor requirements. Depending on the specific configuration and output volume, clients typically see a reduction of 30% to 50% in direct labor costs compared to semi-automated or manual setups. The integrated forming, cooking, assembly, and packaging minimize manual intervention.

Beyond the machine itself, what technical support do you provide?

Our partnership includes comprehensive support: detailed installation & commissioning supervision, thorough operator training programs at our facility, comprehensive operation manuals, responsive remote technical assistance (phone/email/video call), and readily available spare parts supply. We aim to ensure your team is fully equipped to run the line optimally from day one.

How energy-efficient are your hamburger cooking tunnels?

Our cooking systems feature advanced insulation and optimized thermal designs to minimize energy loss. Depending on the heating method and control system precision, energy consumption per patty can be significantly reduced compared to standard equipment. We can discuss efficiency specifications during your project consultation.

How reliable is the equipment?

Reliability and uptime are core to our design. Our hamburger lines utilize high-quality components and robust construction. We proactively recommend a preventative maintenance (PM) schedule based on usage.

Customer Reviews

7 * 24 Support

7 * 24 Support  Remote Support

Remote Support  Global Coverage

Global Coverage