Meat Processing Machines

We provide a comprehensive range of meat processing machines. Moreover, if you are seeking a complete solution for meat processing and packaging, we can offer the right one tailored to your needs.

We provide a comprehensive range of meat processing machines. Moreover, if you are seeking a complete solution for meat processing and packaging, we can offer the right one tailored to your needs.

The chicken feet peeling production line is a professional integrated system designed specifically for chicken feet peeling. It features easy operation and high performance.

The large-capacity chicken feet peeling machine stands as the optimal choice for chicken feet food processing factories and plants, as it enables high-capacity and high-efficiency processing of chicken feet.

The small chicken feet peeling machine is designed for removing the skin from chicken feet. It features easy operation, strong durability, and high performance.

Chicken feet cutting machines are widely used in the pickled chicken feet industry, available in two main types: industrial-grade models and small-scale models.

The poultry feather removal machine can effectively remove the feathers of chickens, ducks, geese, pigeons, quails, and other poultry and birds—all without damaging the poultry’s skin.

The meat dicing machine can precisely cut meat into cubes, slices, shreds, and strips, boasting high working efficiency. Additionally, the cube size is adjustable, ranging from 4mm to 30mm.

The frozen meat slicer is capable of slicing frozen meat (such as pork) into pieces with adjustable thickness—no thawing required.

Commercial meat grinders are capable of processing fresh or thawed meat into strips, slices, chunks, and cubes.

The stuffed meatball machine is designed for producing various types of stuffed meatballs. It can be customized to make meatballs of any size according to your specific requirements.

The meatball forming machine is primarily used for producing chicken meatballs, fish meatballs, shrimp balls, beef meatballs, and other similar products.

The meat smoking machine is designed for smoking sausages, fish, chicken, and other similar products. It supports two heating methods: electric and steam.

The patty making machine can automatically complete filling, forming, gluing, dispensing, and other processes. It is suitable for various raw materials and can produce a variety of products.

The fish scaling machine is designed to automatically and hygienically remove fish scales—without causing damage to the fish body.

Fish cutting machine can cut fish into fillet, segment, strip and block. Suitable for fresh fish, dry fish and slightly frozen fish.

The fish deboning machine separates fish meat from bones by extracting the meat through the sieve holes, offering significant labor and time savings.

The fish rapid cleaning machine features functions such as splitting the fish back, removing fish intestines, and membrane cleaning. Its processing capacity reaches 2,400 pieces per hour.

This sausage tying machine is easy to operate and specializes in sausage production. It boasts a production capacity of 60 pieces per minute, with an adjustable sausage length ranging from 30mm to 300mm. Additionally, it can be operated by a single worker—effectively reducing labor costs and boosting profits.

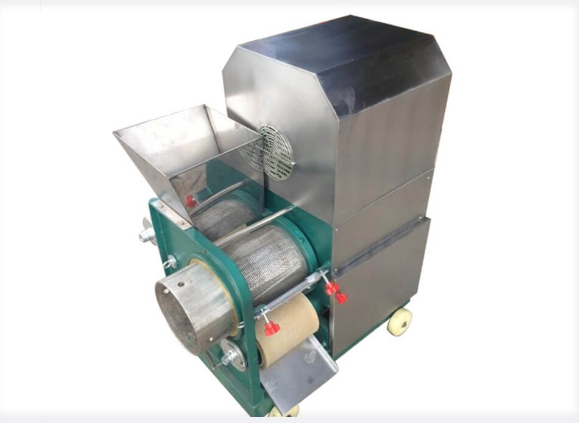

The bone crusher is designed for crushing various types of fresh and dried animal bones, including cattle bones, pig bones, sheep bones, and other similar bones. The fineness of the resulting bone powder ranges from 5mm to 80mm.

The bowl chopper is used to cut meat into fine pieces and mix ingredients into the meat.

The brine injector is used to inject brine into meat for pickling or adding a water solution for tenderization. Suitable for beef, pork, poultry, fish, etc.

The vacuum meat cup can massage and marinate meat in the rotating cup in vacuum state. Suitable for poultry, fish, pork and beef, etc.

The gizzard peeling machine is designed for labor-saving and highly efficient removal of the yellow inner membrane from chicken and duck gizzards.

The gizzard degreasing machine is designed to remove oil from chicken and duck gizzards, preparing them for subsequent processing. It serves as essential equipment in poultry slaughtering lines.

The blast freezer is a specialized freezing equipment primarily used in the commercial sector to rapidly freeze and preserve food products that require frozen storage.

The gas-powered shawarma machine is suitable for use in homes, supermarkets, and trade fairs. It is capable of grilling various types of meat for shawarma preparation.

Membrane skinning is a meat processing procedure that involves removing the membrane and any attached tendons from the meat surface. It is specifically applied to various types of meat, including beef, pork, veal, chicken, mutton, lamb, horse meat, and other similar products.

Automatic meat packing machines automatically weigh, fill, and seal meat into trays, bags, or vacuum packaging. The workflow involves loading the meat into a hopper first; the machine then weighs it to the specified portion size before initiating the packaging process.